Member Article

Croft 3D prints bespoke printer in record time

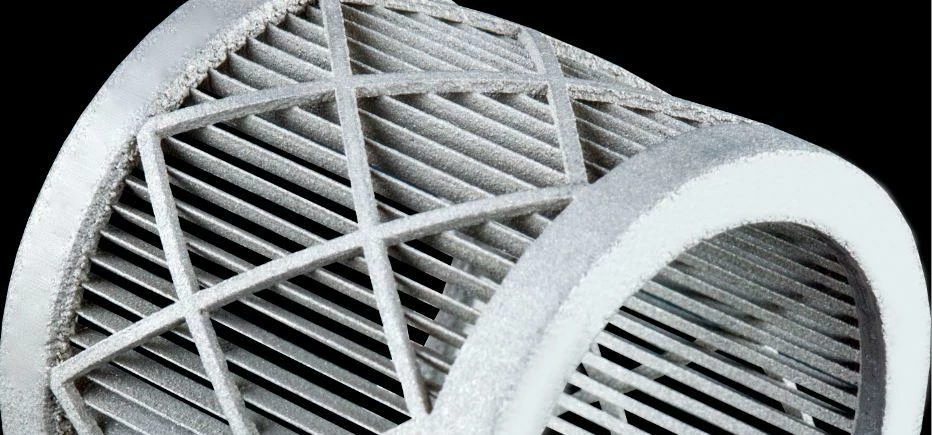

Specialist manufacturer, Croft Additive Manufacturing (CAM), has introduced additive manufacturing (AM) to laboratory and production mixers developers, Eiger Torrance, with a bespoke wedge wire filter.

North West-based Croft was approached by Eiger Torrance, which also develops bead mills, to produce a component required to complete an urgent customer order.

The brief called for a very specific design which, if manufactured traditionally, would take more than a month to provide. As Eiger Torrance needed the component in just two days, the experts at Croft suggested using AM technology.

Croft went on to create a robust AM wedge wire filter, which was designed to increase maintenance cycles in high-pressure applications. As the component has been manufactured as a single piece construction, it also boasts increased strength and rigidity over its subtractively-manufactured counterpart, as well as a significant reduction in weight.

Neil Burns, director at CAM, explained: “The component Eiger Torrance required would typically have a lead time of around four to six weeks for most wedge wire manufacturers. However, as Croft specialises in additive manufacturing, the 48 hour deadline was achievable without compromising on quality.”

Alan Poole, spares and service manager at Eiger Torrance, said: “Croft’s efficient way of working made it possible for us to fulfil a delivery of a client’s new machine on time.

“We were not only impressed by the fast turnaround and high quality of the product Croft delivered, but discovering additive manufacturing has opened up a number of possibilities for our company and we’ll definitely use this innovative technology for a number of our other products in the future.”

Neil concluded: “Additive manufacturing has been around for years but it is only very recently taking off as a viable manufacturing method, as the benefits are increasingly highlighted and understood. We invested in an additive manufacturing machine two years ago to offer our customers innovative products that are not possible to create using traditional manufacturing methods so it’s great to introduce companies, such as Eiger Torrance, to the technology.”

For more information visit www.croftam.co.uk or tweet @Croft_AM

This was posted in Bdaily's Members' News section by Amy Cantrill .

How advancements in technology are shaping the future of the economy in North East England

How advancements in technology are shaping the future of the economy in North East England

South Yorkshire Craftsmanship and Innovation: A Tale of Heritage and Growth

South Yorkshire Craftsmanship and Innovation: A Tale of Heritage and Growth

Demystifying Degree Apprenticeships

Demystifying Degree Apprenticeships

Industry-focused apprenticeships pave the way for a bright future in science manufacturing

Industry-focused apprenticeships pave the way for a bright future in science manufacturing

What’s the best hosting plan for a business website?

What’s the best hosting plan for a business website?