Partner Article

Digital Surveys invests £60k following successful Google work

3D data capture firm Digital Surveys has invested £60k in portable scanning hardware following a successful project with Google.

The Newcastle-based firm can now offer sub mm 3D inspection and reverse engineering services to the oil, gas and engineering sectors.

A recent piece of work for Google required Digital Surveys to scan three light aircraft at an accuracy of plus or minus 25 microns.

The only tool for the job was Creaform Exacan - an industrial grade Canadian product used in the 3D measurement of physical objects.

Paul Livingstone business development Manager at NOF Energy, said: “It is great to see companies such as Digital Surveys rising to challenges such as this and using the experience to drive their businesses forward into new areas.

“To have been selected for the initial project by Google shows the quality of the firm, and the investment it has inspired will continue to help the firm develop its position as a global go-to firm in this market.”

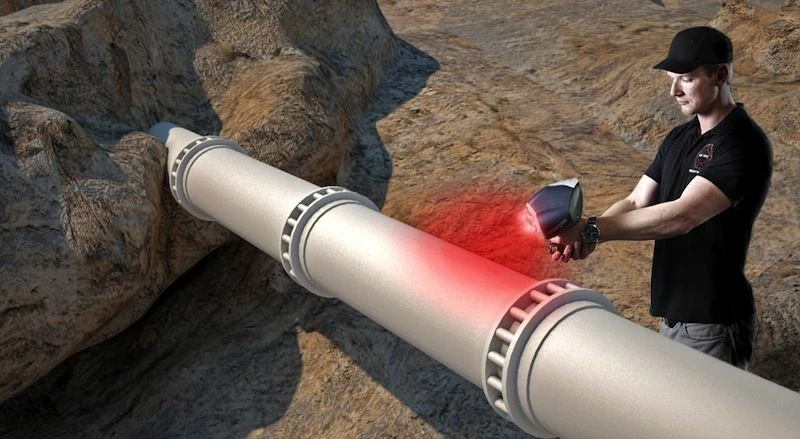

With a scanning resolution of 0.05mm and an accuracy of plus or minus 25 microns, the new scanner will allow Digital Surveys to take on a wide range of new projects in areas including pipeline damage and corrosion inspection.

The new scanner replaces traditional methods like pit gauge and 2D laser measurements to provide very fast, accurate 3D corrosion reports.

It is also ideal for quality assurance and checking of toolings and moulds. These can be scanned and then verified clash/checked against the design models to identify any possible deviations.

Digital Surveys has already used the system to reverse engineer a number of parts from manifolds, valves and exhausts to full assemblies.

The new scanner compliments the firm’s range of equipment, allowing it to provide 3D data capture, digitisation and inspection for almost any application.

This was posted in Bdaily's Members' News section by Tom Keighley .

Enjoy the read? Get Bdaily delivered.

Sign up to receive our daily bulletin, sent to your inbox, for free.

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East