Partner Article

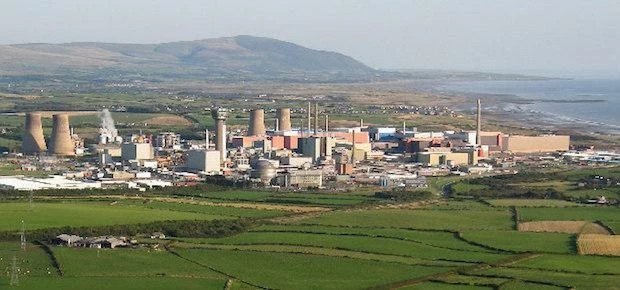

Sellafield remove radioactive sludge in clean up process

Sellafield Ltd announced the first batch of radioactive sludge has been removed from what has been called the most hazardous nuclear plants in Europe.

Sellafield have said this is a ‘huge step forward“ in the UK’s nuclear decommissioning programme.

1500 cubic metres of radioactive sludge is lying at the bottom of a pond, which is equivalent to more than half an Olympic sized swimming pool.

Head of the The First Generation Magnox Storage Pond (FGMSP) Martin Leafe said.

“We’re making history at Sellafield by transferring the first sludge using a tried and tested pump to a new £240 million state-of-the-art sludge storage plant containing three enormous stainless steel buffer storage vessels, each of which is the same volume as seven double decker buses.

“Working with both Westinghouse and Energy Solutions, the technology already in use at European reactor stations has been adapted for our needs at Sellafield and rigorously tested in a full scale test facility at Forth Engineering here in West Cumbria.”

The sludge is a similar consistency to sand and has to be carefully removed while leaving water in place to provide a radioactive shield.

The removal of the sludge from the pond, which holds 14,000 cubic metres of contaminated water, will reduce the hazard posed by the facility.

While the pond has thick reinforced concrete walls, it has no roof and is therefore open to the elements, causing sludge to accumulate at the bottom.

Martin Leafe added: “The pond is six metres deep and we’ve spent years devising an engineering solution to literally suck up the radioactive sludge from the bottom of the pond, which in places is over one metre deep.

“What makes the job more difficult is that the pond is very congested and full of large metal boxes containing nuclear fuel, so we need to work around these and ensure these remain fully submerged at all times.

“Just to make matters more difficult we have to drive the platform remotely from a control cabin to minimize the radiation dose to the workforce.

“We transfer the sludge in batches to the new plant where it settles in one of the enormous buffer storage tanks and then the top layer of water is sent back to the pond.

“It will take several months of work to transfer enough sludge to fully test and commission the sludge plant and in parallel we’ll install the bulk sludge removal equipment.”

The Office for Nuclear Regulation (ONR) lead of the Sellafield Programme, Andy Lindley, said: “The first transfer of sludge is a further significant milestone in our long term aim to drive forward reduction of hazard and risk at Sellafield. This is a complex operation and a first of its kind at Sellafield.

“There will be challenges in removing this material and we acknowledge that there may be some setbacks.

“This is highly hazardous waste and its removal will take some years to complete.

“But the longer term benefit is huge in terms of overall hazard and risk reduction.”

The news comes following the report that the cost of decommisioning Sellafieldhas rocketed to £53bn.

This was posted in Bdaily's Members' News section by Sophia Taha .

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East