Partner Article

Northumbrian Water’s ‘Power from Poo’ production to generate gas as well as electricity

After three years of generating electricity from sewage treatment, Northumbrian Water is expanding its ‘Power from Poo’ production by also creating gas for the national grid.

The water company already leads the way as the only wastewater company in the UK to use all its sludge remaining after sewage treatment to produce renewable electricity.

It captures the biogas released by bacteria digesting the sludge and uses it to drive engines to create electricity.

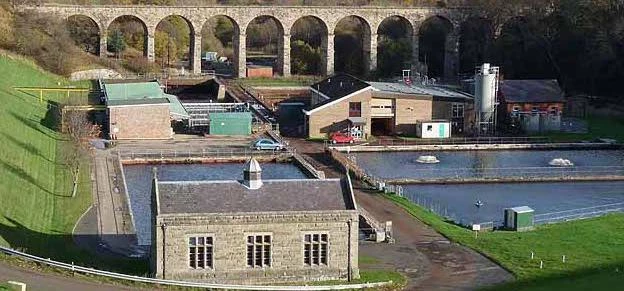

Now Northumbrian Water also has the biggest gas to grid plant of its kind in the industry, cleaning and purifying the biogas to create biomethane which is then injected into the grid. The £8m gas to grid plant is in the final stages of commissioning at Howdon at the mouth of the Tyne.

It has been built alongside Northumbrian Water’s advanced anaerobic digestion (AAD) electricity generation process which has already saved multi-millions of pounds in operating costs and delivered a 20% cut in the water company’s carbon footprint.

Northumbrian Water has two AAD plants, one at Howdon on Tyneside and the other at Bran Sands, Tees Port, Middlesbrough – a previous combined £70m investment in leading green technology.

When fully commissioned the gas to grid plant at Howdon will produce up to 88 million kilowatt hours (kWh) of renewable energy per year - enough to supply the gas requirements of about 5,000 domestic homes. The plant will also deliver a £3m annual efficiency which helps Northumbrian Water have some of the cheapest bills in the industry.

Once the methane has been produced by the AAD plant it is cleaned in water towers in the gas to grid process to remove impurities and propane is added before it is injected so that it matches the existing gas in the grid.

As with natural gas the artificial odour chemical Butyl Mercaptan is also added giving it the characteristic gas smell so it can be detected for safety.

The gas to grid process is more efficient than electricity production as energy is lost as heat and noise from the gas engines used to create electricity.

Richard Warneford, Northumbrian Water’s Wastewater Director, said: “We are now able to produce both gas and electricity. More than 20% of our total power use is now from renewable energy sources including hydro power at our treatment works and reservoirs like Kielder Water.

“Our customers can now be reassured that we are doing all we can to use the waste they flush down the toilet as a fuel and turn it into electricity and gas to add to the national grids which people use to light their homes and cook their meals.

“We are leading the industry in pushing the bounds of technology and learning from the challenges of integrating the new gas plant with our existing advanced sewage treatment and electricity generation processes.”

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our daily bulletin, sent to your inbox, for free.

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East