Partner Article

Oberlin Filter in £350k Newton Aycliffe expansion project

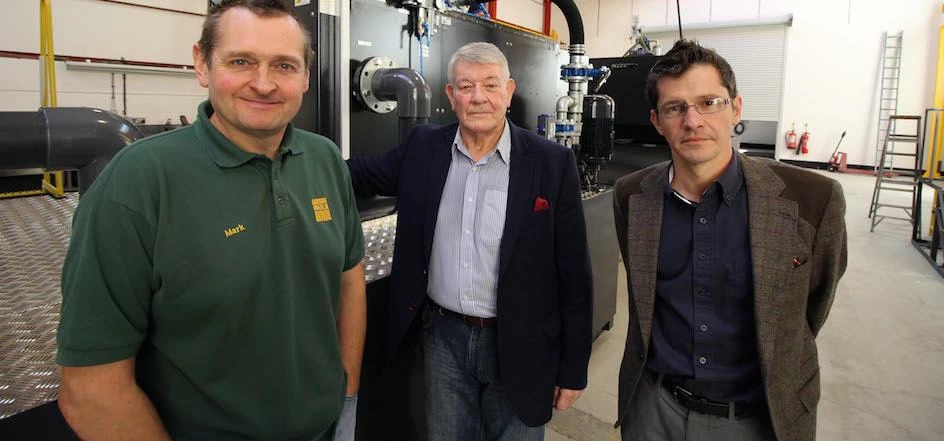

The UK arm of a US-owned global filtration manufacturer has moved to larger premises at Newton Aycliffe Business Park, an expansion project costing £350k.

Oberlin Filter produces automatic pressure filtration units for a number of companies in heavy engineering, medical, aerospace, surface treatment and automotive sectors, among others.

Its filtration machines assist in the production of industrial gas turbine blades, vanes and segments within aerospace, gears, valves, valve seats and crankshafts within automotive sectors as well as joint replacement devices such as knee and hips in the medical industry.

Oberlin Filter is owned by a private, family-run business, based in Wisconsin, USA, while there is also a production facility in Eschweiler, Germany.

Its UK operation was established in 1998 to further develop its market in the UK, Ireland and throughout Europe particularly the Netherlands, Belgium and France.

Oberlin began production in Newton Aycliffe in 2002, originally in one small unit on Gurney Way, Aycliffe Business Park, as the business gradually expanded over the early years it amalgamated three neighbouring units.

But after outgrowing them, the company has now moved to new 11,000 sq ft premises on Hurworth Road in a relocation costing £350k, which has included the £40k purchase of a 10-tonne moving crane from nearby firm Durham Lifting.

The new facility will enable Oberlin Filter and its Aycliffe team of seven to maintain recent growth after doubling turnover to £1.8m in the last few years and explore new markets.

The firm’s sales engineer Mike Johnson said: “Essentially we design and manufacture automatic pressure filtration units for any kind of liquids that need solids removing.

“We work with companies in chemical processing, sulphur recovery, edible oil, pharmaceutical and water treatment or sludge dewatering - basically any liquid/solid separation, particularly when either has a re-usable or re-saleable value.

“Our systems clean the liquid while the solids are discharged and dried automatically - and we bring every part of this very technical and scientific system together in-house right here in Newton Aycliffe.”

As well as manufacturing filtration systems, Oberlin Filter’s team boasts a range of other skills at its new Aycliffe operation, including electrical panel building, welding, fabrication, control system design and PLC programming, while it also has a new large spray booth.

The sale of consumables, principally filter media, is another area of valued growth within the business.

“Within our new surroundings we now strategically stock more to complement our growing customer base – not only for Oberlin filter equipment users,” said Mike.

However, the company’s main line of work comes with the production of their filtration systems, which can cost anywhere between £50k and £200k per unit.

Mike added: “There are many others, who manufacture filtration units, but our technology and experience allows us to penetrate dynamic and evolving, precision based markets. Typically industries where metal working requires grinding and high pressure, high volume coolant control management.

“We’ve established several new clients in the aerospace and medical sectors in recent years after recognising these markets as growth areas for us. We hit £1.8m turnover a couple of years ago, maintained this but hit capacity in our former location. Now we have the space to continue growing again.

“We’re manufacturing on average 12 filtration systems a year and we’re currently working on our 100th build here in Newton Aycliffe, which is a fantastic milestone for us. We’ve invested £40k in a new 10-tonne, overhead moving crane and one or two other rather expensive investments to complement floor space and the capacity, which will help to make us more efficient.

“The short-term aim is to maintain current growth over the next couple of years. The long-term goal is to develop active business relationships with further grinding machine manufacturers beyond the three-fold increase of the last three years and other key market areas such as hot frying oil, within the food industry, water treatment, sulphur recovery and pharmaceutical.”

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our daily bulletin, sent to your inbox, for free.

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East

Time to stop risking Britain’s family businesses

Time to stop risking Britain’s family businesses

A year of growth, collaboration and impact

A year of growth, collaboration and impact

2000 reasons for North East business positivity

2000 reasons for North East business positivity

How to make your growth strategy deliver in 2026

How to make your growth strategy deliver in 2026

Powering a new wave of regional screen indies

Powering a new wave of regional screen indies

A new year and a new outlook for property scene

A new year and a new outlook for property scene