Partner Article

Miller invests £1.5m on efficient technology in plant overhaul

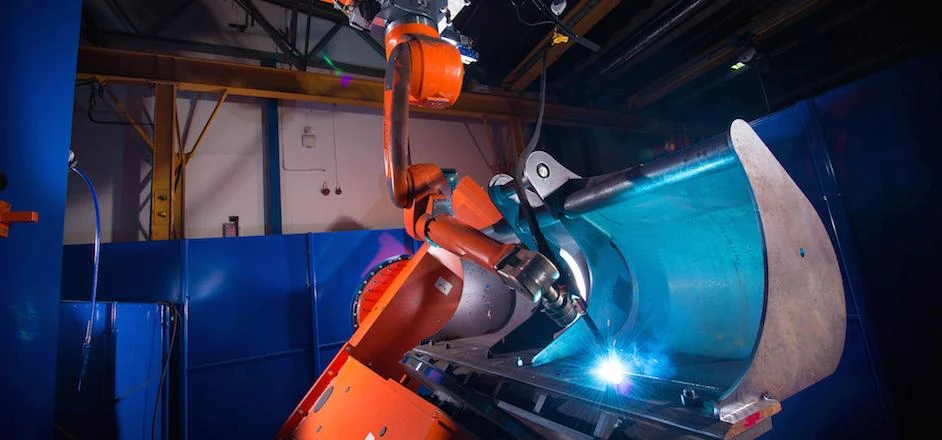

Cramlington-based Miller, the earthmoving attachments company, has invested almost £1.5m to introduce new technology at its UK manufacturing plant, as part of an overheaul.

Centralised on bucket manufacture, the investment has focussed largely on three key areas: productivity. This will ensure that the industry will continue to be serviced by a UK company.

Improvements include: the implementation of the latest robotic equipment to optimise capacity during busy trading periods, two plasma cutting machines and a dynamic parts storage system, designed to increase manufacturing productivity. This, coupled with planned stock building during quieter periods, ensures availability is guaranteed on all fast moving products.

Mike Askew, managing director at Miller, said: “This initial investment, which is part of a major long-term plan designed to guarantee that we can continue to provide high quality, competitively priced attachments. It demonstrates our commitment to manufacturing in the UK.

“Continual investment in our product range and manufacturing processes is vital to ensure we’re able to meet the needs of our customers while remaining competitive in a global marketplace.

He added: “We’re looking firmly ahead now and by creating a lean and efficient manufacturing process, we are confident that we’re ready to tackle any future challenges head on.”

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our daily bulletin, sent to your inbox, for free.

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East