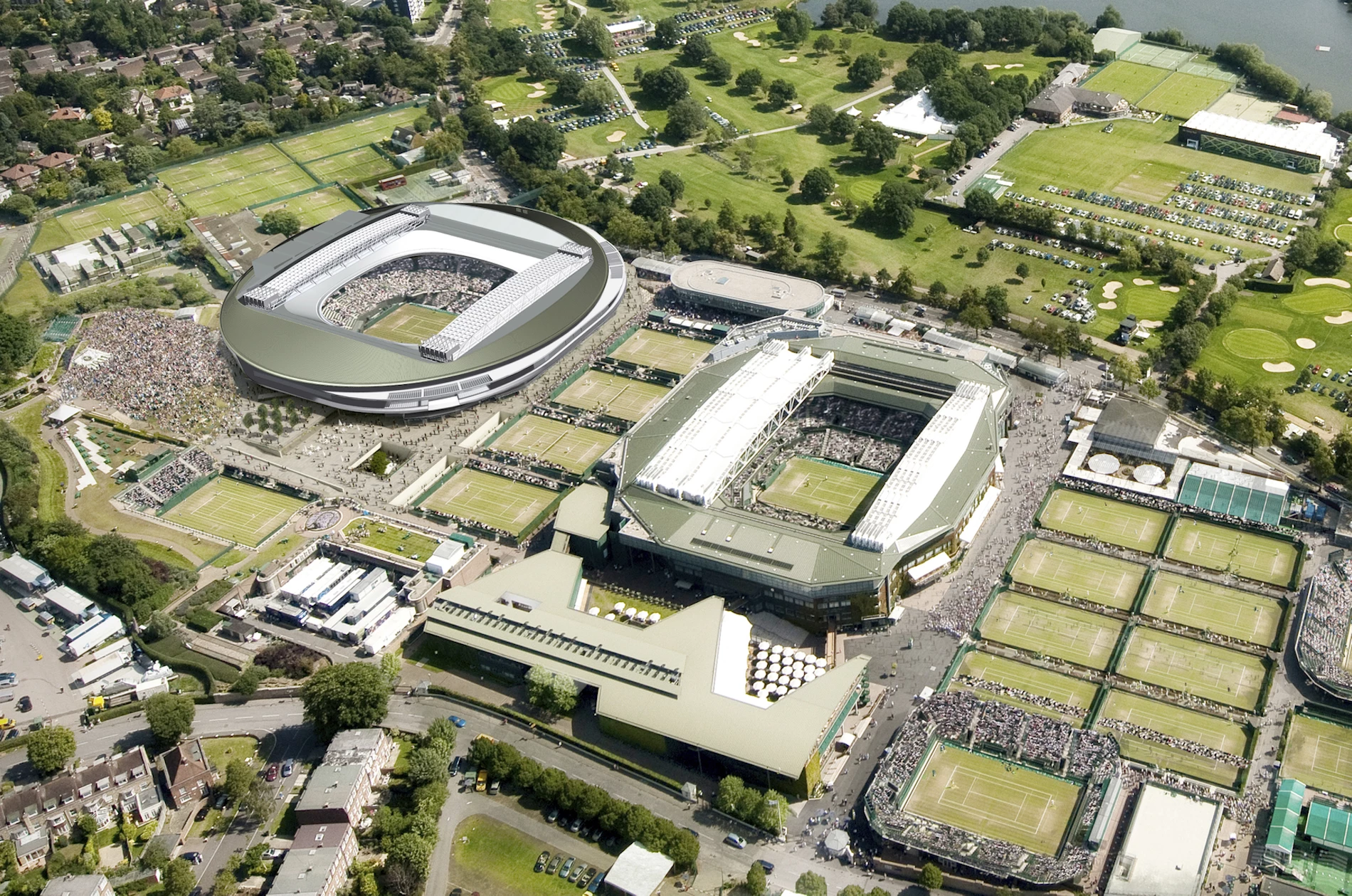

Engineering group to complete Wimbledon No.1 Court roof scheme for next year’s tournament

SCX, the Sheffield-based engineering group, is set on raising the roof at The All England Lawn Tennis Club, Wimbledon in 2019.

The beginning of next year’s tournament will mark the completion of a three-year project to engineer and install a retractable roof over No.1 Court.

SCX Special Projects was awarded the contract in 2016 after designing, assembling and installing a similar retractable roof over Wimbledon’s Centre Court in 2009.

After this year’s Championships, the trusses for the folding roof will start to be raised into position over No.1 Court.

The retractable roof is part of a multi-million pound redevelopment which will mean that like Centre Court, No.1 Court will guarantee play whatever the weather.

Andy Whitworth, director of SCX Special Projects, said: “We are delighted with the progress on the new roof, which will be ready in time for next year’s tournament. 2019 also happens to be the tenth birthday of the retractable roof on Centre Court.

“The roof over No.1 Court is another landmark project for SCX and an iconic example of the engineering solutions and skills we employ. SCX is now recognised as one of the leading builders of moving structures in the UK and this contract has helped to take our order book to record levels.”

The steel roof trusses for No.1 Court, each weighing 80 tonnes, were made in Sheffield and delivered to Wimbledon before the latest Championships. They are being stored on two former practice courts ready for installation and mechanical and electrical testing by SCX’s engineers.

Robert Deatker, estate director, AELTC, commented: “It’s an impressive stadium in its own right and will create a whole new atmosphere for people coming to No.1 Court.”

SCX has refined its concertina design used for the first retractable roof over Centre Court.

The new No.1 Court roof uses 11 steel trusses in two sections, with transparent Gore Tenara (a type of Gore-Tex fabric) stretched between them, allowing light into the stadium while keeping it weatherproof. It can be fully deployed or retracted in around eight minutes.

SCX is responsible for the design and supply of all the mechanical and electrical equipment, and for the construction of all the components that make up the moving sections of the roof.

Much of the preliminary construction, assembly and testing work was carried out at SCX’s new Tyler Street facility in Wincobank, Sheffield.

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our popular morning London email for free.

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East