Partner Article

Derby Company Wins Prestigious Locomotive Engineering Award

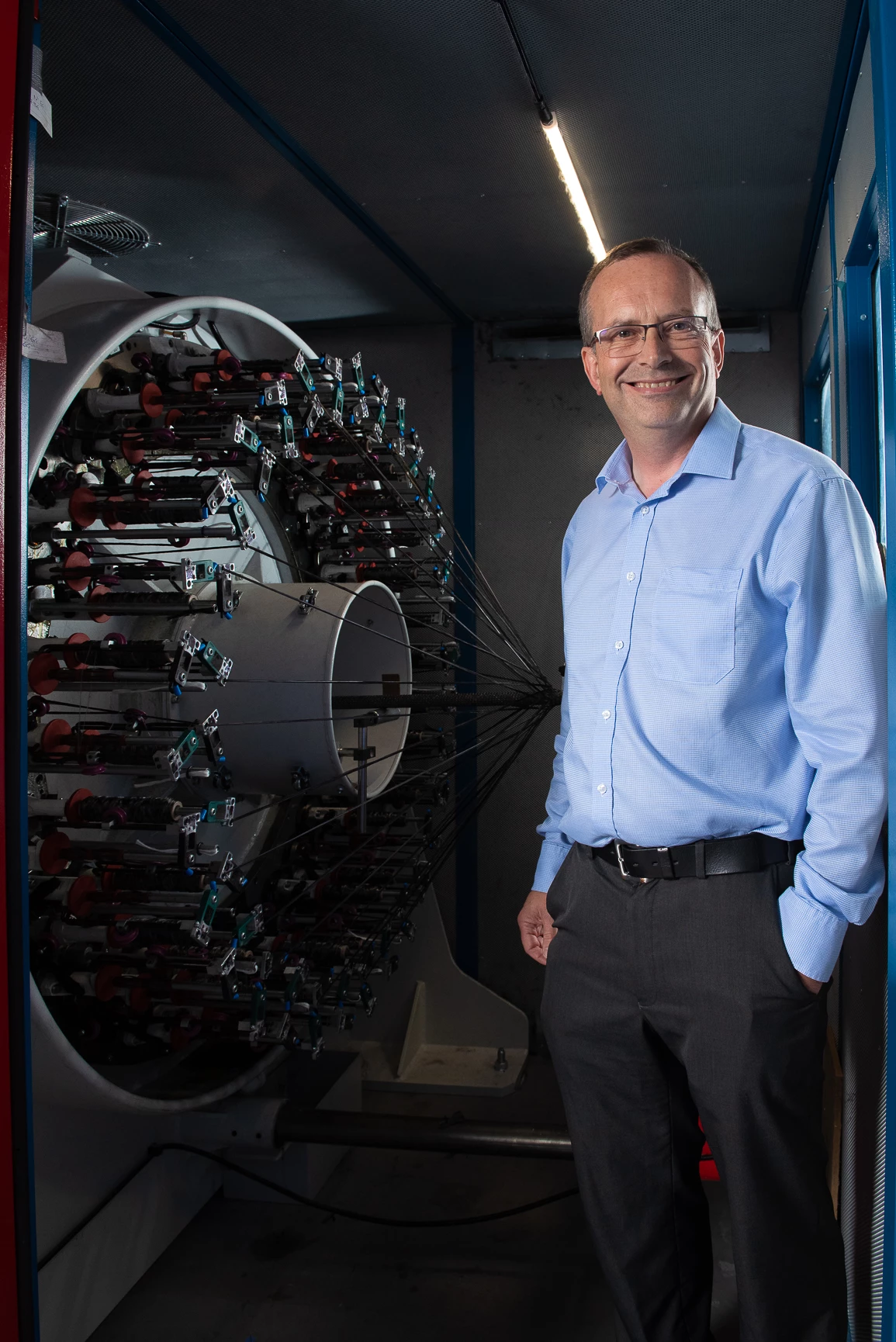

Composite Braiding, a manufacturing firm specialising in thermoplastic composite braiding technology, has won a prestigious award at the Global Light Rail Awards 2019.

The firm, which is based at the iHub on Infinity Park, alongside a consortium of manufacturers, has won ‘Technical Innovation of the Year’ for the project to design a lightweight alternative to the metal frames of train carriages.

The Global Light Rail Awards recognise excellence and innovation in the global light and urban rail sector and are regarded as the ‘Oscars of the light rail industry’. The winners in 17 categories were announced at an awards ceremony at London’s Honourable Artillery Company, which were hosted by broadcaster and journalist Nicholas Owen.

Composite Braiding and partners FAR-Composites, Transport Design International (TDI) and the Warwick Manufacturing Group (WMG), operating under the name ‘Project Brainstorm’, designed, developed and manufactured a prototype spaceframe as a light-weight structural solution for (Very Light Rail) VLR application.

Over a 15 month period, the consortium developed a braided composite tubular frame which was more lightweight, cheaper and comparatively stronger than a metal alternative. The process also proved to be better for the environment and easier to fix than the standard metal frames.

Composite Braiding specialises in thermoplastic composite braiding, an innovative process which provides a stronger, tougher and more flexible alternative to woven composites. By combining thermoplastic with a composite material, braided structures are tailored to meet demands and performance criteria across any sector.

The company operates from a hybrid working environment at the 45,000ft2 iHub, the centre- piece of Infinity Park, the new 100-acre commercial and technology site, located between Sinfin and Chellaston.

As well as traditional office space, the firm occupies two state-of-the-art workshops totalling over 1,700ft2, which has enabled it to establish its own manufacturing capability.

Judges praised the winning submission for its innovation, vision and ambition to create not only new manufacturing processes, but potentially a whole new industry:

One said:

“This is what the industry has been waiting for decades. Aviation and automotive do this already, so it’s great to see a UK consortium bringing us up to that level. I can’t wait to see the first full vehicle next year.

“This was one of the toughest years yet to choose the winners. It is fantastic to see so many joint entries, showing that industry partners are sharing best practice and expertise as we all look to bring down costs, improve safety and sustainability and deliver the best possible passenger experience.” Speaking on the success of the project, Steve Barbour, managing director of Composite Braiding, said:

“We are delighted to have won this prestigious award. This has been an incredibly challenging but rewarding project and its success comes from the commitment, expertise and energy of our dynamic team. By combining our knowledge and resources we have been able create an innovative, cost-effective solution and demonstrate the potential benefits to the light rail sector and the passenger populations it serves.

“The outcomes and impacts achieved by the Brainstorm project could be adopted quickly by light rail manufacturers or developed and adapted for additional applications within transportation and engineering.”

Ann Bhatti, head of Connect Derby, added:

“Congratulations to Steve and his consortium for winning such a high-profile national award.

“Composite Braiding is one of a number of companies which have helped the iHub establish a reputation for creating cutting-edge ideas in the aerospace, automotive and transport engineering industries and we would like to wish Steve and his consortium partners every success with this exciting new venture.”

The iHub, which has Enterprise Zone status, provides high quality, flexible workspace for start-ups, early stage businesses and high growth SME’s looking to establish, or expand their role in the transport engineering and hi-tech sectors. The £12m facility has attracted a diverse range of businesses from across the rail, aerospace and automotive supply industries. As well as 18 traditional office workspaces, it features 14 ground floor workshops for businesses seeking a more hybrid working environment.

An addition to the facilities at the iHub is the innovative ‘iLab’, which promotes invention by enabling the rapid prototyping of a range of products and services. It features high end virtual reality, 3D printing and surface microscope equipment.

The building also offers a multi-purpose ‘heart space’ area, available for hosting external conferences and events, along with meeting and seminar rooms.

The development has received funding from the D2N2 Local Enterprise Partnership and European Regional Development Fund (ERDF), as well as Derby City Council and the University of Derby.

This was posted in Bdaily's Members' News section by Donna Hill .

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East