Partner Article

‘European first’ for SDE Technology as it targets £multi-million of new lightweight opportunities

One of the UK’s leading manufacturers of pressings and assemblies has signalled its intentions to be a world leader in lightweight components by investing in a new process.

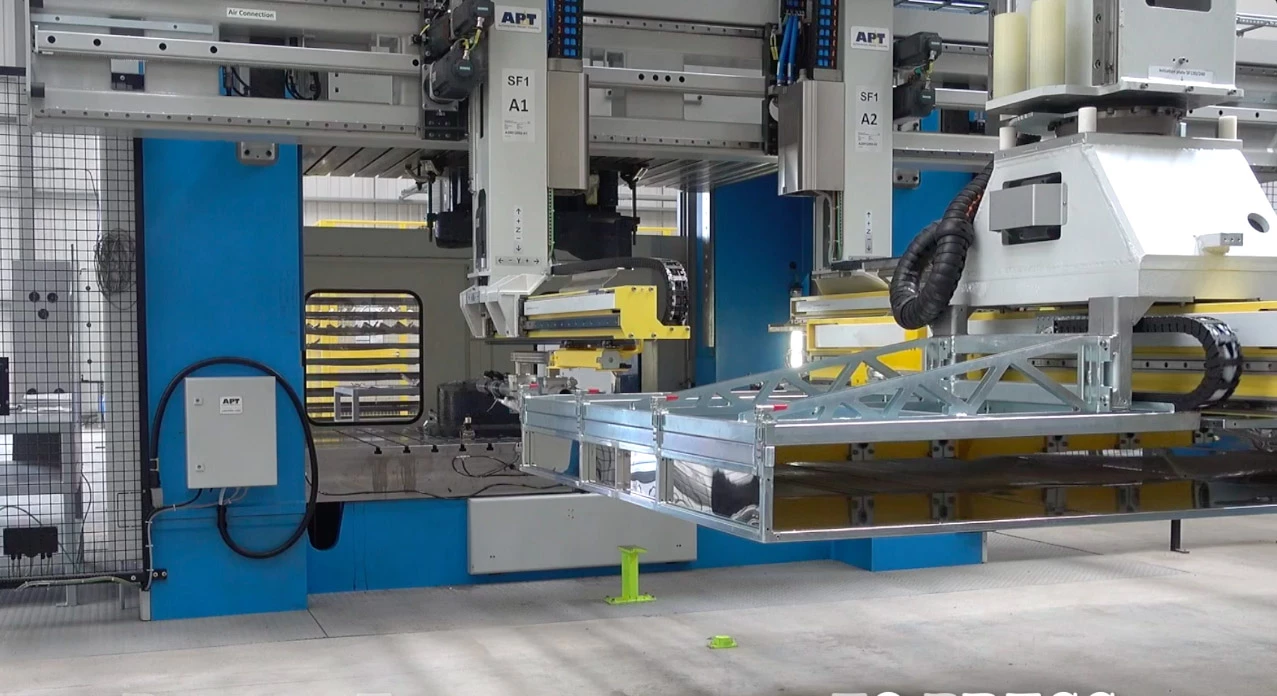

SDE Technology, which prior to the recent rebrand was known as Salop Design and Engineering, is the first company in Europe to hold a production licence for Hot Form Quench (HFQ®), a revolutionary hot forming process for producing high strength aluminium parts for use in the automotive, aerospace and renewable sectors.

This new technology gives designers the freedom to create parts that offer significant weight savings, yet still deliver higher structural strength, with improved formability in six and seven thousand series alloys, that cannot be formed cold. In some instances, it can also reduce the part counts from multiple components to just one.

Because HFQ lends itself to higher strength aluminium, it is ideally suited for the vehicle safety cell in the automotive sector and has also been used to develop a prototype aircraft armrest.

The initial investment of £1 million in 2019 enables the laser profiling of HFQ blanks, with a £multi-million investment scheduled to be in place at its Shrewsbury facility over the next eighteen months.

“This is a real gamechanger for our business and industry as a whole - thanks to HFQ® we can now offer new and existing customers a lightweight solution for making complex parts in one pressing, reducing weight, time to manufacture and cost in the process,” explained Richard Homden, CEO of SDE Technology.

“HFQ® was developed by Impression Technologies (ITL), who industrialised research by Birmingham University and Imperial College London. This is a great example of British research being utilised by British manufacturing.”

He continued: “You simply cannot form this high-strength aluminium in any other way, unless you use a Super Plastic Forming process. Even then, SPF makes one part every 15 to 20 minutes, where the cycle time for our technology is one part every 15 to 20 seconds. That is a design and manufacturing dream.

“This is the start of an ambitious growth and investment strategy that positions us as the first production intent company for this process in Europe.”

SDE Technology is currently in talks with a number of OEMs about the Hot Form Quench offer.

Initial feedback from clients point to the fact you can exchange steel parts for aluminium and achieve part integration and less weight as the key drivers for adoption. The fact you can also remove reinforcements and replace extrusions and castings with HFQ® pressings are other big wins.

Christopher Greenough, Chief Commercial Officer, said: “As a company, we are focused firmly on how we can deliver lightweight manufacturing solutions that can help solve a lot of industry’s current and future requirements.

“The Government is obviously pushing hard for electrification and this is something that our technology can assist with and we believe this will be a big driver in helping quadruple our turnover over the next 5 years.”

Mark White, a leading technical specialist in lightweight vehicle structures, added his support: “I have been actively involved in the trend for lightweighting and, now that the Government’s push to EV is accelerating, it is more important than ever to find innovative ways to enable it to become the design norm.

“SDE Technology is leading the way with its HFQ licence and will provide the production route for OEMs to access this exciting process.”

Christopher concluded: “We are looking to be at the forefront of the emerging EV and lightweighting markets, whether it is through HFQ or other innovative processes for joining different materials, battery technology and surface coating.”

For further information, please visit www.sde.technology or follow @sde_technology on twitter.

This was posted in Bdaily's Members' News section by Russ Cockburn .

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East