Yorkshire manufacturing business wins multi-million pound contract to build net zero bricks

A Yorkshire manufacturing business has won a new contract to supply the first net zero brick facility in the UK.

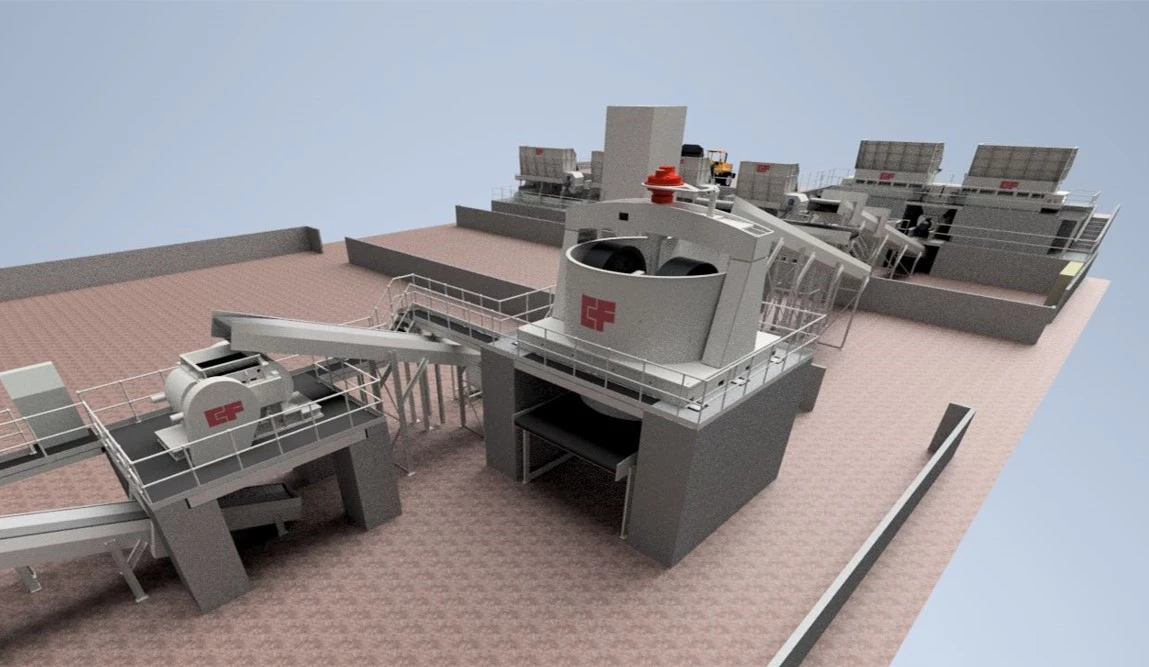

Wakefield-headquartered Craven Fawcett, one of Europe’s leading manufacturers of clay preparation and extrusion machinery and part of Group Rhodes, will see the company design, build, and manufacture a fully integrated state-of-the-art clay preparation and extrusion line at Ibstock’s Atlas site in the West Midlands.

The news follows Ibstock plc’s announcement of £60m investment in its Atlas and Aldridge plants, which will collectively deliver an additional 115 million brick capacity per annum.

Glynn Dixon, contracts manager at Craven Fawcett, said: “Ibstock has been a highly valued customer of Craven Fawcett for almost 40 years. We are naturally very pleased with this major new contract win and are looking forward to designing and building this bespoke cut clay brick line to further enhance Ibstock’s strong market position.”

Andrew Craddock, engineering and manufacturing development director at Ibstock Brick, commented: “As a supplier to Ibstock for many years, we are aware of the capabilities of Craven Fawcett in designing and building new production lines to meet our exacting requirements.

“This is an important undertaking and we are pleased to be working with a UK partner that not only has the expertise in clay preparation and extrusion technology, but also understands Ibstock’s holistic approach to its corporate business sustainability strategy.”

Mark Ridgway, OBE DL, CEO of Group Rhodes, added: “We are delighted to be working with Ibstock on this exciting project which has great product design and UK manufacturing at its heart.

“As a business, we are committed to good environmental practices and are pleased to be able to support projects where improved sustainability is a critical outcome. Goods will be sourced with low environmental impact, and we will be working with local suppliers wherever possible.”

It is also expected that Craven Fawcett’s sister company, Hallamshire Engineering Services will be supplying conveyor drums and rollers to the project. The Ibstock contract is expected to take approximately 24 months through to final commissioning.

Looking to promote your product/service to SME businesses in your region? Find out how Bdaily can help →

Enjoy the read? Get Bdaily delivered.

Sign up to receive our popular Yorkshire & The Humber morning email for free.

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector

Why investors are still backing the North East

Why investors are still backing the North East