Partner Article

Rugby auto firm accelerates thanks for local funding

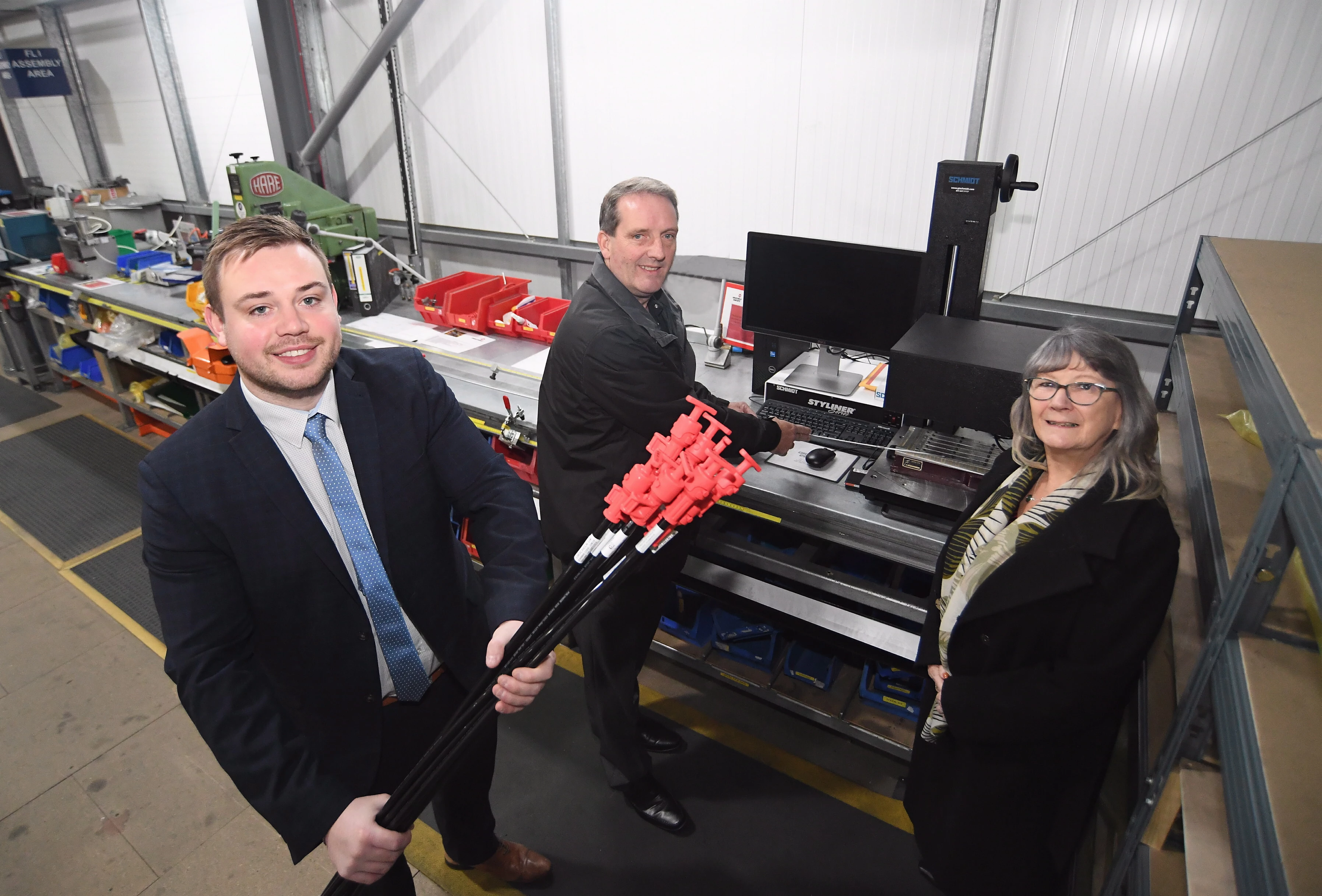

An automotive company is expanding its operations in Rugby after receiving a grant to buy a new machine.

Orscheln Europe assembles mechanical cables, accelerator pedals, shifter assemblies and fluid level indicators (FLIs) for the On-Highway (Truck and Bus), Off-Highway (Construction and Agricultural Vehicles), Aircraft, Military and Speciality markets from its 12,163sq ft base at Central Park in Pelham Road.

Customers include DAF Trucks, Leyland Trucks, Volvo Trucks, CNHi, Caterpillar, Renault Defence, Terberg, Cummins Engines, Perkins Engines, Pilatus and Piaggio.

The business, whose parent company is based in the USA, has 11 distributors of its products spread across the UK and Europe including in Nottingham, Southampton, Germany, Spain, Italy, Greece, Denmark, Norway and in the Ukraine.

Pete Smith, general manager at Orscheln Europe, said the business had previously used a hand engraving machine to etch the blades in the FLI assemblies for low volume orders but he wanted to make the process more efficient.

He contacted Adam Plumb at the Coventry and Warwickshire Local Enterprise Partnership (CWLEP) Growth Hub for advice, and he advised him to apply to Rugby Borough Council for its Additional Restrictions Grants (ARG) scheme which was introduced by the government post-pandemic to help companies speed up their expansion plans.

Orscheln Products received a grant of £14,785 and invested a further £12,000 in the FLI Production Cell to buy a state-of-the-art machine from GT Schmidt in USA, the same machine used at their USA Plant.

Pete explained: “Previously, we brought low volume FLIs and prototypes from our sites in North America and India which has long lead times, that can be problematic for our customers.

“The hand engraving machine that we used could not replicate the quality of the automated engraving machine and was very repetitive for our workforce but having the grant meant we could invest in a machine for engraving the blades which is so much more efficient and provides our customers with a higher quality and lower lead-times.

“We want to grow that side of the business because we can speed up the processes for our customers which appeals to them and by bringing this side of the business in-house it will help us do that.

“It is the first time we have had a grant from Rugby Borough Council and it was a really easy process. We had a lot of help from Adam at the Growth Hub who has been absolutely superb and very supportive and I didn’t realise we could apply for it until he mentioned it.”

Adam also put Pete in touch with his colleague Rich Hales from the Growth Hub’s Employment Solutions portal – which is a free service for job seekers, employers, recruiters and education leavers to find jobs, post vacancies and access support measures across the region – when he had a vacancy for a technical sales position which has now been filled by Jonathan Hamilton to take Orscheln Products’ workforce up to 15.

Adam Plumb, account manager at the CWLEP Growth Hub, said part of the Growth Hub’s service was to make businesses aware of funding available to help them grow.

He said: “Orscheln Europe is a perfect example of the type of business that the Additional Restrictions Grants project was launched to help.

“Installing this new machine will save time and money and improve its efficiency which means they can bid for more work and have the capacity to take on more orders which is great news.”

Cllr Carolyn Robbins, Rugby Borough Council portfolio holder for finance, performance, legal and governance, said: “Working in partnership with CWLEP Growth Hub, we have targeted nearly £1 million in Additional Restrictions Grants to support the borough’s economic recovery from the pandemic, backing businesses in the borough with robust plans for growth.

“I’m delighted we’ve been able to help Orscheln Europe invest in new equipment which allows the company to increase efficiency, improve the quality of its products and generate more work.”

This was posted in Bdaily's Members' News section by Matt Joyce .

The value of using data like a Premier League club

The value of using data like a Premier League club

Raising the bar to boost North East growth

Raising the bar to boost North East growth

Navigating the messy middle of business growth

Navigating the messy middle of business growth

We must make it easier to hire young people

We must make it easier to hire young people

Why community-based care is key to NHS' future

Why community-based care is key to NHS' future

Culture, confidence and creativity in the North East

Culture, confidence and creativity in the North East

Putting in the groundwork to boost skills

Putting in the groundwork to boost skills

£100,000 milestone drives forward STEM work

£100,000 milestone drives forward STEM work

Restoring confidence for the economic road ahead

Restoring confidence for the economic road ahead

Ready to scale? Buy-and-build offers opportunity

Ready to scale? Buy-and-build offers opportunity

When will our regional economy grow?

When will our regional economy grow?

Creating a thriving North East construction sector

Creating a thriving North East construction sector